Use case 01.- Structural Integrity of Steel Components

Automated compliance checking for structural integrity of modular steel members

The UK demonstration case focuses on enhancing the efficiency and reliability of compliance checks of structural integrity by integrating advanced digital tools and methodologies. It seeks to leverage the latest technological advancements in BIM and structural analysis to ensure that modular housing components meet the Euro codes in terms of strength checks of structural steel members. This involves utilising BIM-based inputs and Finite Element Analysis (FEA) to assess and verify compliance with relevant building regulations.

This demonstration case is innovative in its use of Semantic Web technologies to automate compliance checks. It employs a proprietary tool to bridge open-source FEA software with BIM data, enabling automatic verification against regulatory requirements through advanced data processing and ontology management. This integration represents a significant step forward in the digitisation of compliance processes in the building sector.

Case description

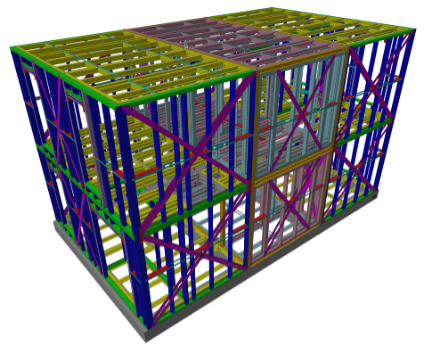

The case is a lightweight structural steel modular house developed by a UK-based manufacturer specializing in cold-rolled lightweight steel. This manufacturer operates a modular construction business using its own cold-rolled lightweight steel products and has its own offsite building systems. Figure 1 shows the lightweight steel modular pods produced in the factory of the case provider. In this study, they provided information including an IFC model of a generic modular house used for production purposes. This building system enables the adoption of either panelised or volumetric methods for production and assembly, with cold-rolled lightweight steel profiles as structural members forming the building frame, including the walls and floors. The generic modular house is designed to be adaptable to typical UK low-rise residential typologies such as terraced, semi-detached, and detached houses. This is considered a practically useful case study, combining a relatively straightforward structure with a detailed IFC model (Figure 2) used for both design and manufacturing purposes, while describing a system with wide applicability and adaptability.

Figure 1 Lightweight steel pod produced by the case provier

Figure 1 Lightweight steel pod produced by the case provier

Figure 2. Structural BIM model of the offsite module (Source: Patlakas et al (2024)

Approach

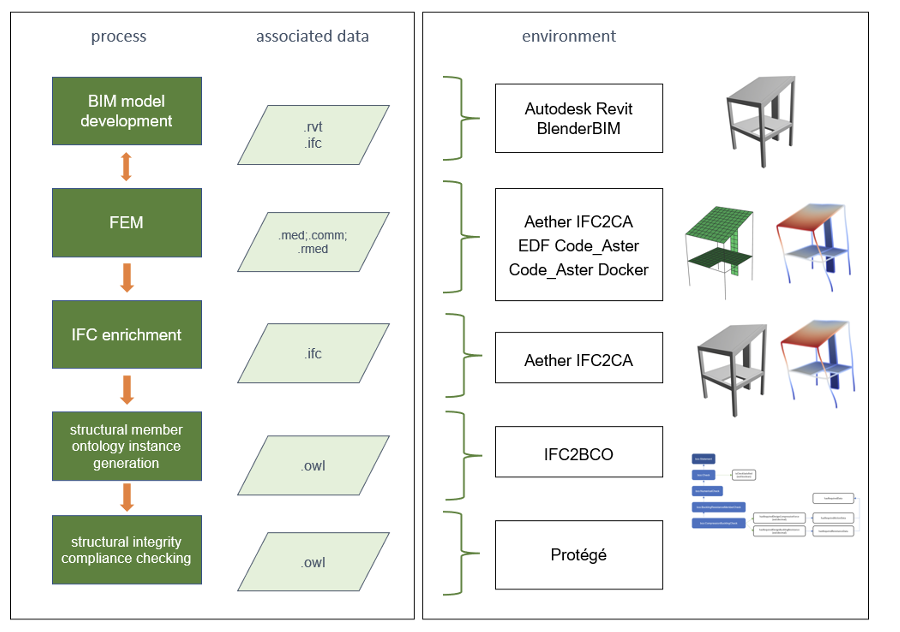

The overall workflow starts with the creation of an IFC model that incorporates detailed geometry and material information. This model serves as the foundation for subsequent analyses. The model is first validated against Integrated Design Specifications (IDS) to ensure it meets all required parameters for structural integrity checks. Following the model validation involving using an open-source FEA solver, Code_Aster, to conduct detailed structural analyses. This enriched model then undergoes a series of compliance checks against established building regulations, which are automated through the development of a proprietary middleware tool, IFC2BCO. This tool facilitates the transformation of enriched BIM data into semantic web-compatible formats that can be processed for compliance verification. The enriched data is subsequently introduced into Protégé, a semantic web tool where compliance is automatically checked against relevant statements of the Building Regulations using SHACL, a language for expressing conditions and constraints. This step is visually represented in Figure 3 of the UK demo case document, which provides a flowchart of the data processing and compliance checking stages. The sample process for structural engineering analysis is shown in Figure 3.

Figure 3 Sample process for structural engineering analysis (Source: Patlakas et al (2024)

Exploitation

The approach has been reported in the paper entitled Semantic web-based automated compliance checking with integration of Finite Element analysis (Patlakas et al, 2024). The technologies developed are expected to have applicability potential. They can significantly impact how compliance checks are conducted across the construction industry, potentially becoming a standard tool for engineers and regulatory bodies. The practicability and scalability of the approach will be evaluated by the modular case provider.

Reference

Patlakas, P., Christovasilis, I., Riparbelli, L., Cheung, F. K., & Vakaj, E. (2024). Semantic web-based automated compliance checking with integration of Finite Element analysis. Advanced Engineering Informatics, 61, 102448.